The significance of building hardware in modern construction projects cannot be overstated. According to a recent report by the International Alliance for Sustainable Construction (IASC), approximately 40% of construction costs are attributed to hardware materials, underscoring the critical role that building hardware plays in the overall efficiency and sustainability of construction efforts. With the increasing complexity of architectural designs and the push for energy-efficient structures, the demand for high-quality building hardware has reached unprecedented levels, necessitating innovative solutions that not only meet regulatory standards but also optimize project timelines and budgets.

John D. Miller, a recognized expert in construction technology, emphasizes, "Quality building hardware is the backbone of any construction project—without it, structures cannot achieve the durability and safety they promise." His insights reflect a broader industry consensus that prioritizing premium building hardware is essential for ensuring that modern constructions can withstand the rigors of time and environmental factors. As infrastructure needs evolve and urbanization accelerates, integrating advanced building hardware into construction practices will be vital for the industry’s progression toward sustainable development and enhanced safety standards. This growing emphasis illustrates why a strategic focus on building hardware is indispensable for successful modern construction projects.

In modern construction projects, the integration of hardware solutions plays a pivotal role in enhancing efficiency and productivity. Hardware encompasses a broad range of tools and equipment that facilitate various tasks, from fundamental building processes to advanced installation systems. The use of high-quality hardware can significantly reduce time spent on tasks, allowing teams to maintain timely project completions. Additionally, specialized hardware can streamline workflows, making it easier for workers to access the tools they need without delays, which ultimately boosts overall site productivity.

Moreover, the right hardware solutions contribute to improved safety standards on construction sites. By utilizing durable and reliable tools, teams can minimize the risk of equipment failure, which is often a leading cause of accidents. Proper hardware not only ensures that tasks can be completed more effectively but also fosters a safer working environment. Enhanced safety measures lead to fewer injuries and lower insurance costs, creating a more sustainable operational model for construction companies. By prioritizing the development and implementation of efficient hardware, construction projects are better equipped to meet today’s demands and challenges.

| Hardware Type | Functionality | Efficiency Gain (%) | Typical Applications |

|---|---|---|---|

| Heavy Machinery | Excavation and Earth Moving | 30% | Site Preparation, Road Construction |

| 3D Printers | Rapid Prototyping of Structures | 40% | Residential Projects, Custom Components |

| Drones | Site Surveying and Monitoring | 25% | Inspections, Mapping |

| Robotic Arms | Precision Construction Tasks | 35% | Bricklaying, Welding |

| Modular Components | Pre-fabricated Building Parts | 50% | Commercial and Residential Buildings |

The construction industry is experiencing a transformative phase, driven by enhanced building techniques and advanced tools that significantly increase efficiency and reduce costs. According to a recent report by McKinsey & Company, adopting digital tools can lead to a productivity increase of 14-15% in construction projects. These tools include Building Information Modeling (BIM), drones, and augmented reality, which facilitate better planning, design, and collaboration among teams.

Advanced tools play a crucial role in modern construction by enabling precise project visualization and real-time data analysis. For instance, the use of drones allows for accurate site surveying and monitoring, reducing the time needed for physical inspections by up to 80%. Moreover, BIM enhances communication by providing a shared platform for architects, engineers, and contractors, minimizing errors and rework. A study by the National Institute of Standards and Technology (NIST) indicates that the implementation of BIM can lead to a 10-20% reduction in construction costs.

Tips: When integrating advanced tools into your construction projects, prioritize training for your team to maximize the benefits. Consider starting with pilot projects to assess the effectiveness of new technologies before a full-scale rollout. Additionally, maintaining open communication channels can significantly enhance collaboration and help tackle challenges effectively. Embracing these innovations not only streamlines processes but also positions your construction firm as a leader in the evolving market.

The integration of hardware and technology in project management has transformed the way modern construction projects are executed. Utilizing advanced hardware tools such as drones, 3D printers, and IoT devices enables project managers to streamline operations, reduce errors, and enhance communication among teams. These technologies not only automate tedious tasks but also provide real-time data, allowing for better decision-making and more efficient resource allocation. The implementation of such hardware facilitates the visualization of projects through augmented reality, enabling stakeholders to comprehend designs and modifications effectively.

Moreover, the collaboration between hardware and technology enhances safety protocols on construction sites. Advanced monitoring systems can track the health and performance of equipment, while wearable technology ensures that workers are adhering to safety standards. By leveraging these tools, project managers can predict and mitigate risks, leading to a safer working environment. This synergy between hardware and technological innovations not only optimizes project workflows but also contributes to higher quality outcomes, paving the way for future advancements in the construction industry.

This chart illustrates the importance of various hardware technologies integrated into modern construction projects, showcasing their impact on efficiency, safety, and overall project completion time.

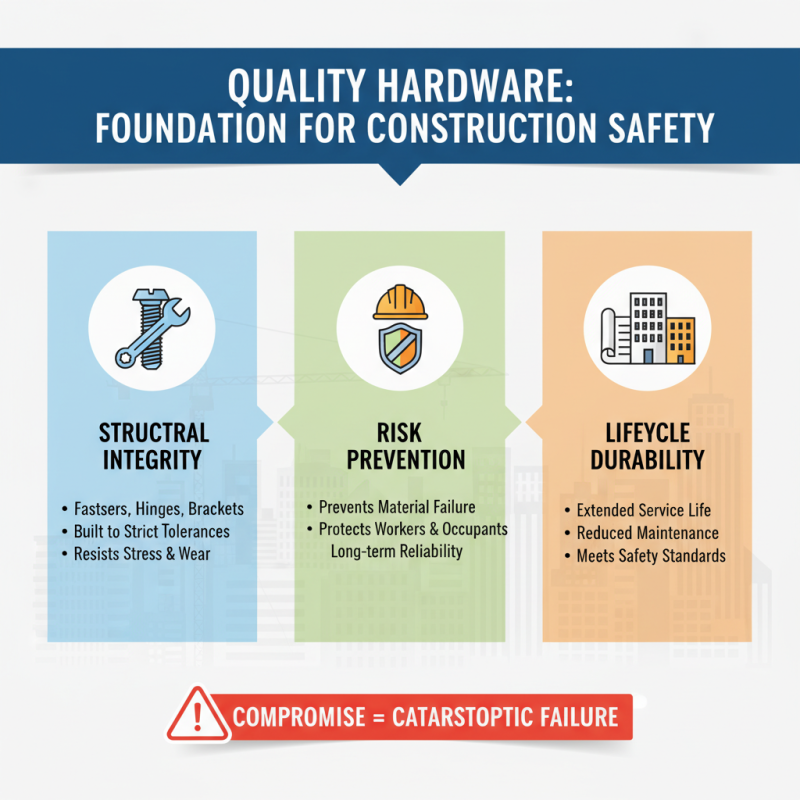

Quality hardware plays a pivotal role in ensuring safety standards within modern construction projects. The integrity of a structure often hinges on the robustness and reliability of the materials and components used. For instance, fasteners, hinges, and support brackets must be manufactured to stringent tolerances and standards to withstand the various stresses they will encounter throughout a building's lifecycle. Any compromise in the quality of hardware can lead to catastrophic failures, putting workers and occupants at risk.

Moreover, the role of hardware extends beyond mere structural support; it is integral in compliance with safety regulations. High-quality hardware contributes to the overall resilience of a building, making it better equipped to handle environmental challenges such as earthquakes, severe weather, or overloading. When the right hardware is utilized, the risk of accidents decreases significantly, and construction teams can adhere more closely to safety protocols. Thus, investing in quality hardware not only enhances the durability of construction projects but also fosters a culture of safety that protects everyone involved.

The future of hardware development in construction projects is poised for significant transformation, driven by technological advancements and an increasing emphasis on efficiency and sustainability. One of the most notable trends is the integration of smart technology into construction hardware. Sensors and IoT devices are being embedded into machinery and tools, allowing for real-time monitoring and data collection. This enables project managers to track equipment performance, predict maintenance needs, and optimize workflows, ultimately reducing downtime and increasing productivity on construction sites.

Additionally, the emergence of sustainable materials and modular construction techniques is reshaping the hardware landscape. Innovations in materials science have led to the development of eco-friendly alternatives that reduce the carbon footprint of construction projects. Modular construction, which involves prefabricating components off-site, not only speeds up the building process but also minimizes waste and energy consumption. As these trends continue to gain traction, construction hardware will evolve to meet the demands of a more environmentally conscious industry that values efficiency, safety, and resilience in its operations.